Photos

“P-2000-S” 4-Piece

“P-2000” General Purpose- 4-Piece / Free Floating Check Ring / High Abrasion

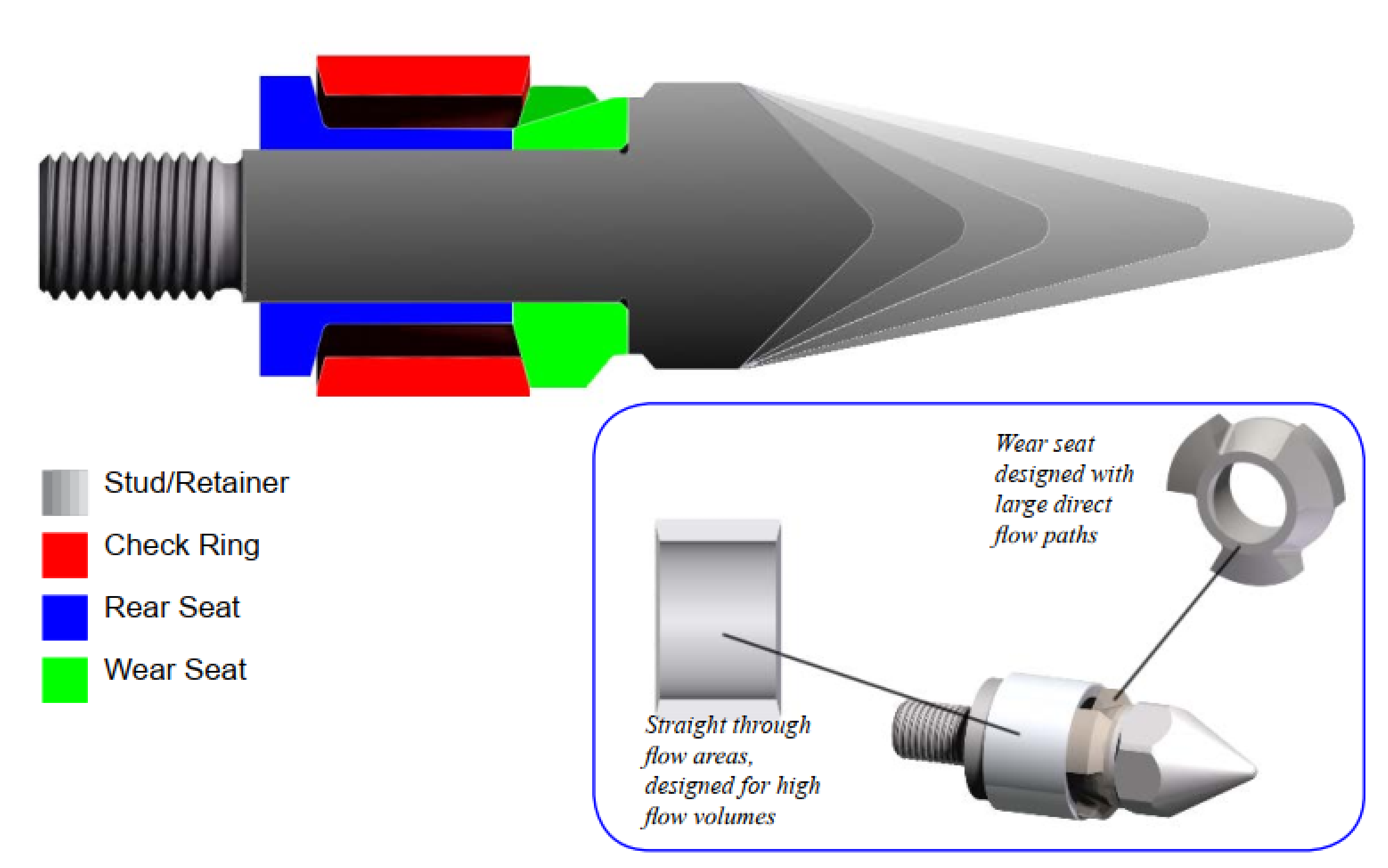

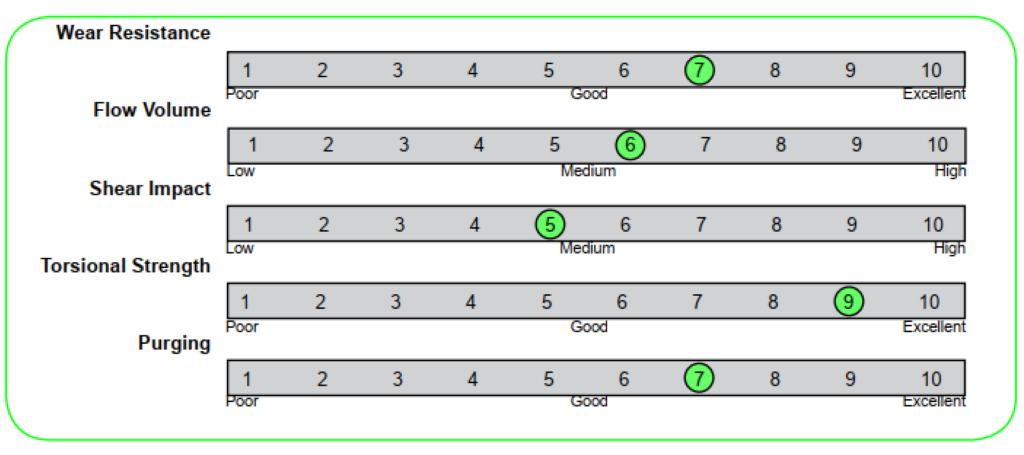

The design offers excellent wear resistance on the main replaceable wear components – the ring, wear seat and rear seat. These are combined with an extremely high tensile strength retainer (stud) to withstand shock or rigors of improper starting.

The geometry of the wear seat using three large high flow material paths, cut at gentle angles that blend into the retainer, provide greater and more streamlined flow than similar 4-piece designs. The check ring’s straight-through design improves the flow volumes and creates less pressure drop. This allows for a faster screw recovery even with high viscosity or highly filled polymers.

Specifications

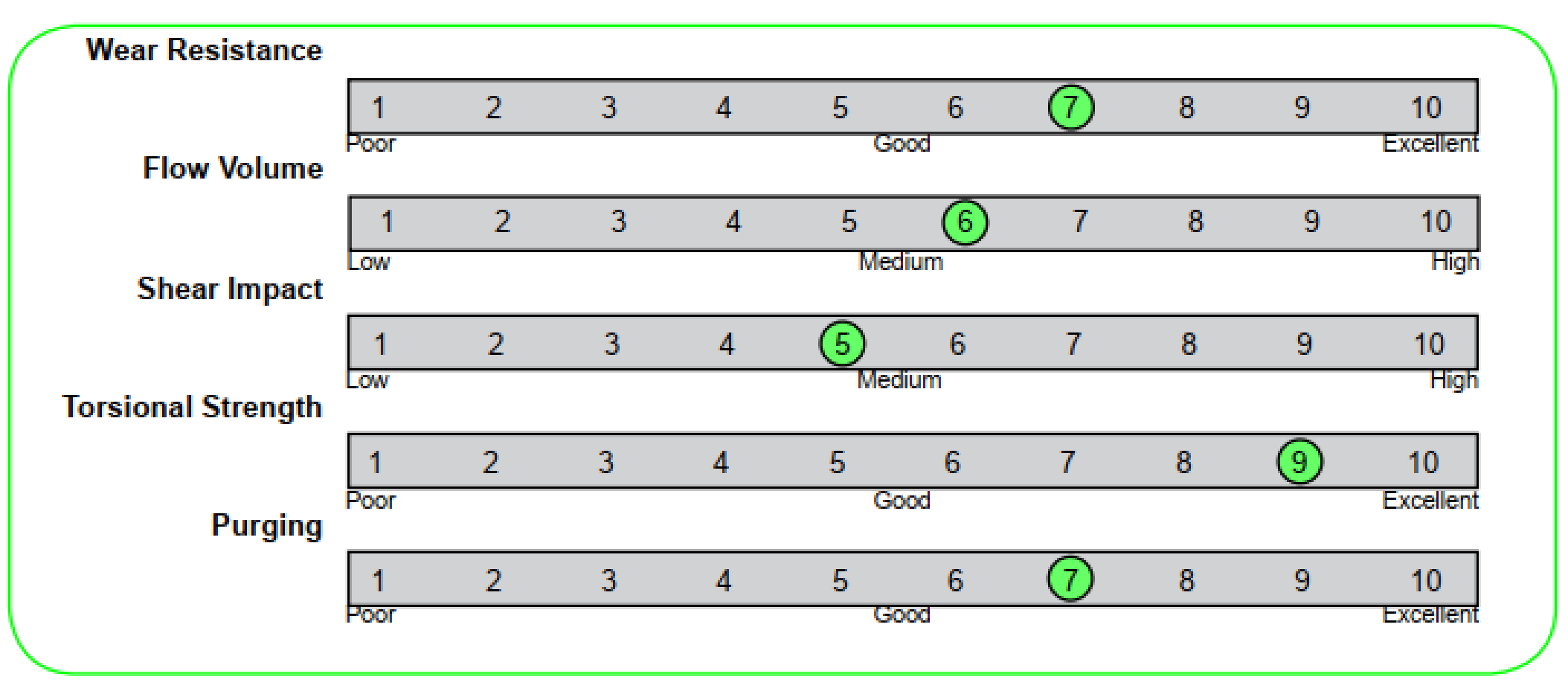

“P-2000-S” General-Purpose- 4-Piece /High Abrasion/ High Flow:

| Designed with generous flow volumes and direct, highly polished flow paths, this valve provides very little pressure drop. Providing fast screw recovery rates, it’s easy and fast purging for material and color changes. | ||

|---|---|---|

| Materials: | The key wear components are manufactured from high quality tool steels containing very high levels of the carbide forming element Vanadium which is one of the hardest and most wear resistant carbides. The retainer (stud) is manufactured from 17- 4PH stainless steel and is standard on ring sizes of 2.50” (65mm) or less and optionally offered on larger sizes. Larger sizes are manufactured from pre-heat-treated 4150 alloy steel. These materials have tensile strengths greater than 185,000 PSI, which is up to two times greater than materials commonly used on 3-piece design valves. This provides excellent torsional strength to absorb twisting and bending forces that can cause stud breakage. | |

| Recommended Applications: | This design provides real value for larger size machines and applications using very high viscosity polymers or materials with very high levels of fillers. Long fiber materials will benefit from the gentle and generous flow paths, resulting in less fiber damage and a stronger molded parts. | |

| Limitations | This design will not perform well with low viscosity polymers in terms of cushion or shot control. Also, it may not perform well on applications requiring high or moderate screw speeds or that utilize greater than 75% of the injection capacity. The abrasive action of the ring-to-wear seat contact at fast or prolonged use will generate heat that may anneal the hardness of the tool steel. |

|