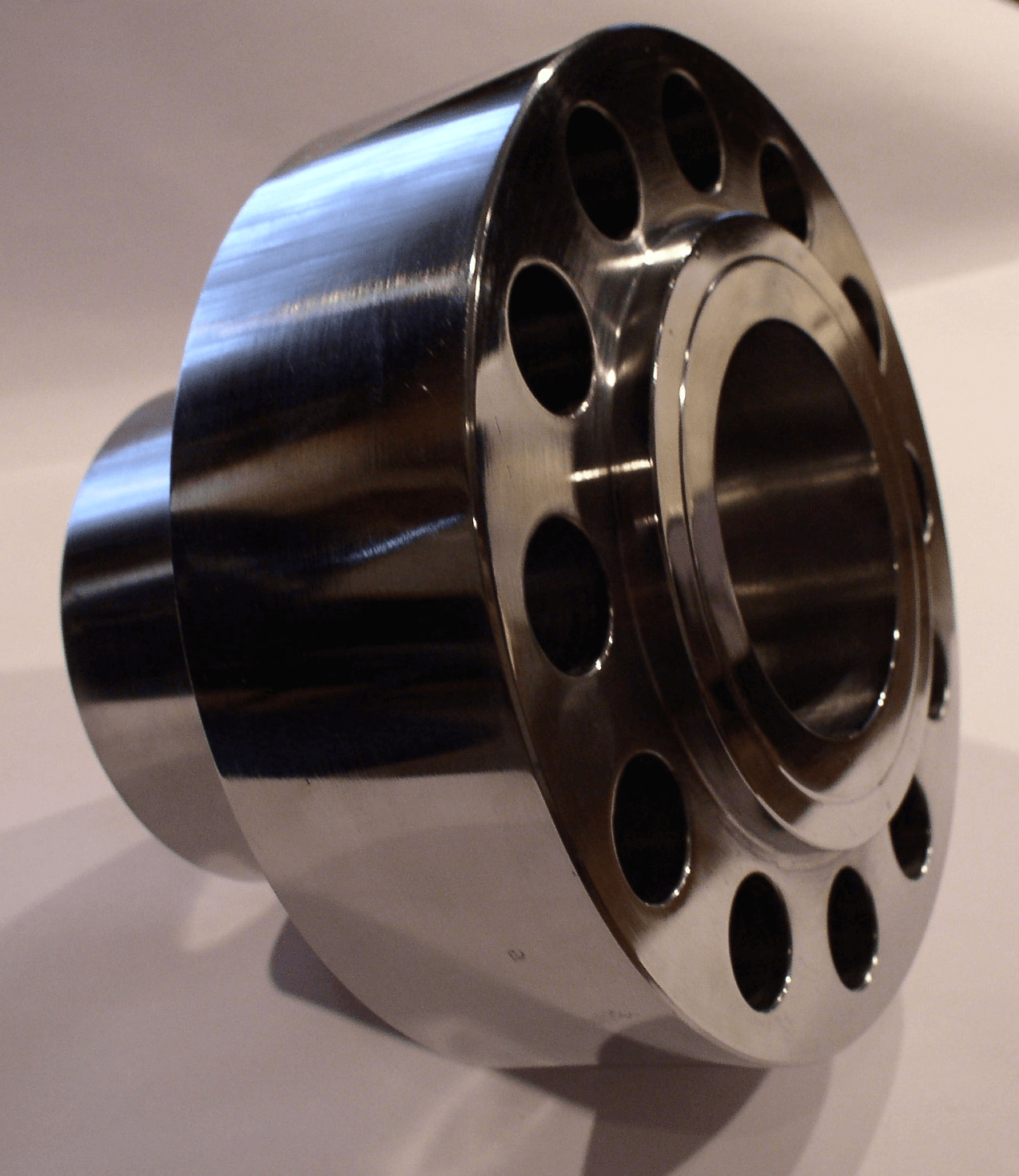

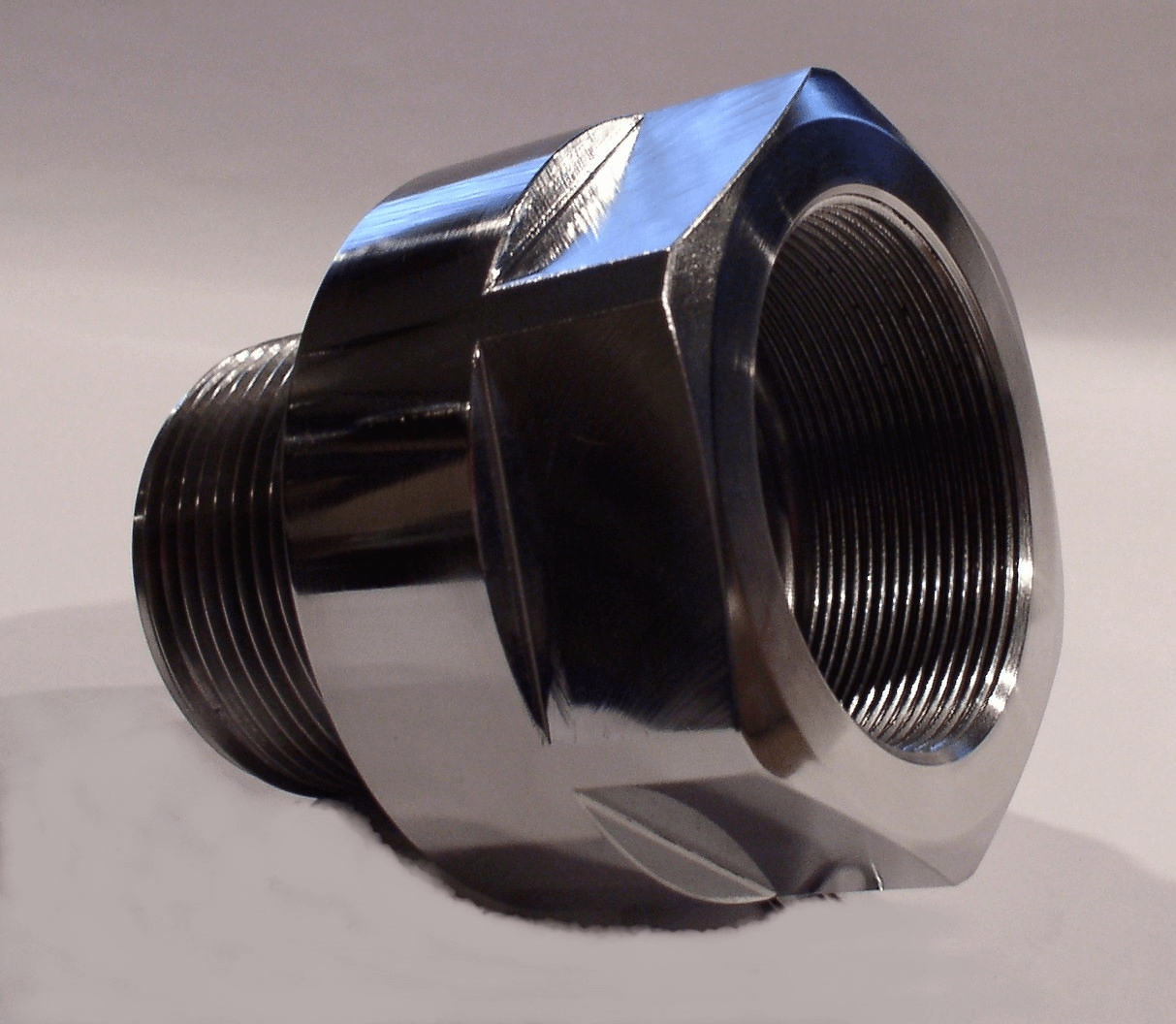

Plasti-Co® high-quality precision end caps for injection molding and extrusion machines play an important role, working in tandem with the nozzle and barrel to deliver material to the mold and eliminate material degradation. The End Caps require the right combination of features including, strength, heat resistance, corrosion resistance, high polish finish, and proper taper to match the end cap and tip, all to meet the needs of your precise plastics processing applications.

At Plasti-Co®, our expert staff of engineers and manufacturing provide the best value and highest-quality products that has made us become a leader and trusted partner for injection and extrusion end caps in the plastics market.

Top End Cap Manufacturer

We focus on the unique needs of your process, system and applications, as one size does not fit all when it comes to end caps. Whether a standard or a custom design, the Plasti-Co® team will evaluate your specific process and machine requirements, work with you to find the solution to deliver the end cap, that meets your overall needs and materials. Let our experienced staff take the lead and find your solution, using our expertise and care, used on our entire line of products, to provide you with the highest-quality end caps.