View Our Current Barrel Promotions

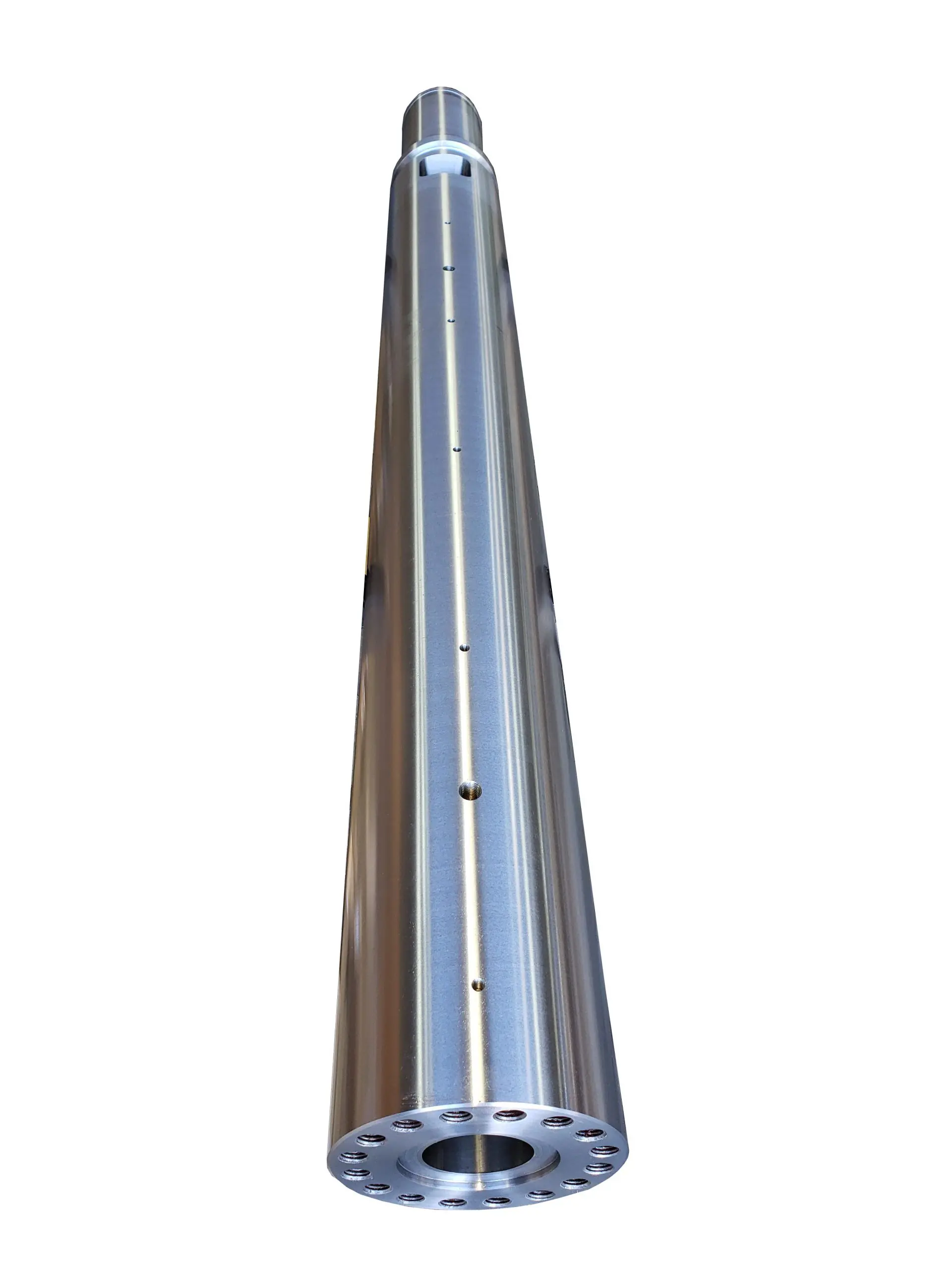

The barrel of a molding machine is one of the most important components, supporting the rotating and/or reciprocating screw and having consistent heat distribution across the entire barrel. The barrel must be well-suited to the demands of the machine and the materials being processed. Plasti-Co® offers a wide range of barrels for extrusion and injection molding machines, as well as repair services & support, utilizing our expert technicians.

Give Us a Call at 810.227.2266

Types of Barrels for Molding Machines

The type of barrel you utilize for your extrusion or injection molding machine will affect many aspects of your injection or extrusion system, which is why it’s so important to choose the right one. Your budget, your efficiency and your finished products will thank you. Our Sales, Technical Support Engineers and Customer Service are ready to help you.