Photos

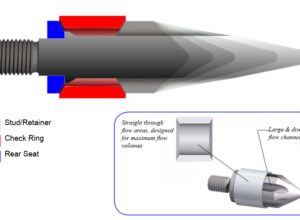

“P-700” 3-piece

“P-700” General-Purpose- 3-piece / Free Flow

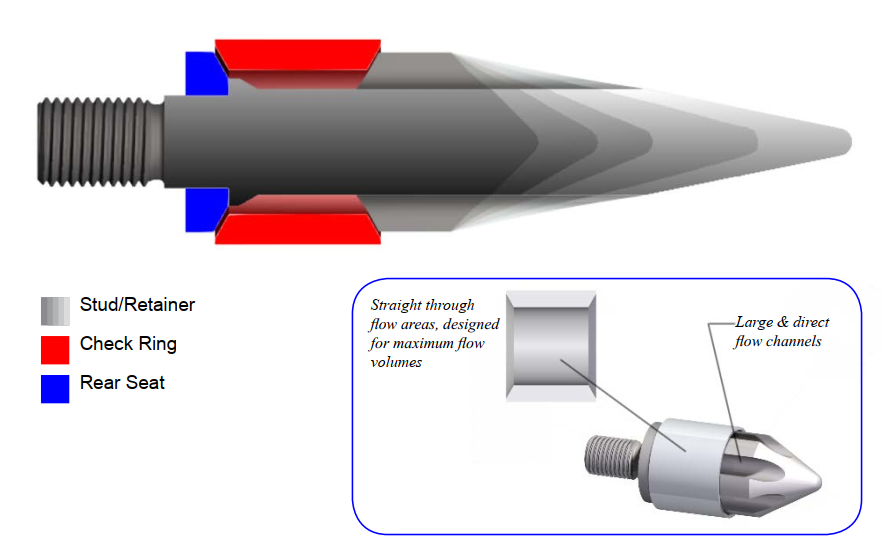

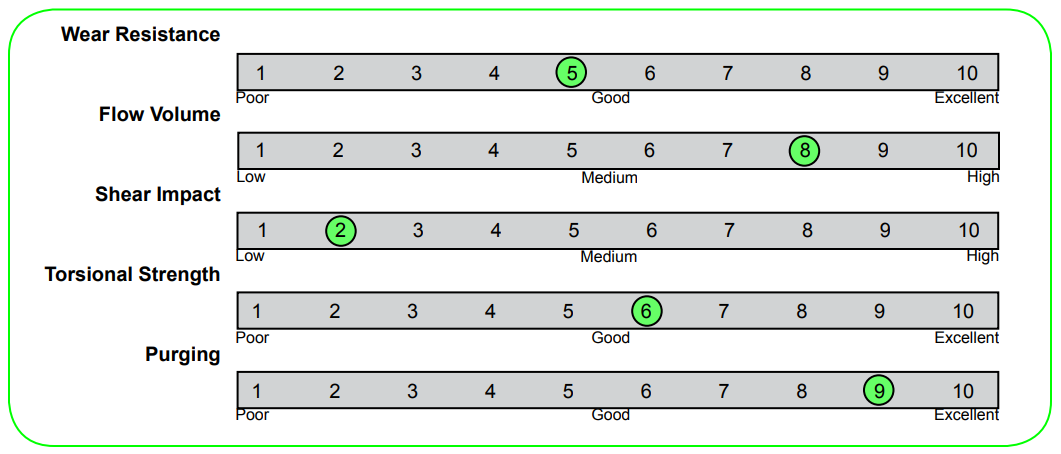

Designed with generous flow volumes and direct flowing, highly polished flow paths. Manufactured from H-13 tool steel that is heat-treated as well as Ion Nitride surface hardened for added wear protection.

Specifications

“P-700” General-Purpose- 3-piece / Free Flow:

| Designed with generous flow volumes and direct flowing, highly polished flow paths, this valve provides very little pressure drop; providing fast screw recovery rates, easy and fast purging for material and color changes. The P-700 design leaves very little dead space forward of the feed screw for maximum displacement of the polymer. | ||

|---|---|---|

| Materials: | All three components of the P-700 screw tip are manufactured from H-13 tool steel that is heat-treated to the maximum safe Rockwell hardness, based on the valve geometry that will range from 52 to 59. The components are Ion Nitride surface hardened for added wear protection. Nitride provides a case hardness of up to 70 Rockwell with a case depth up to .015” per side. | |

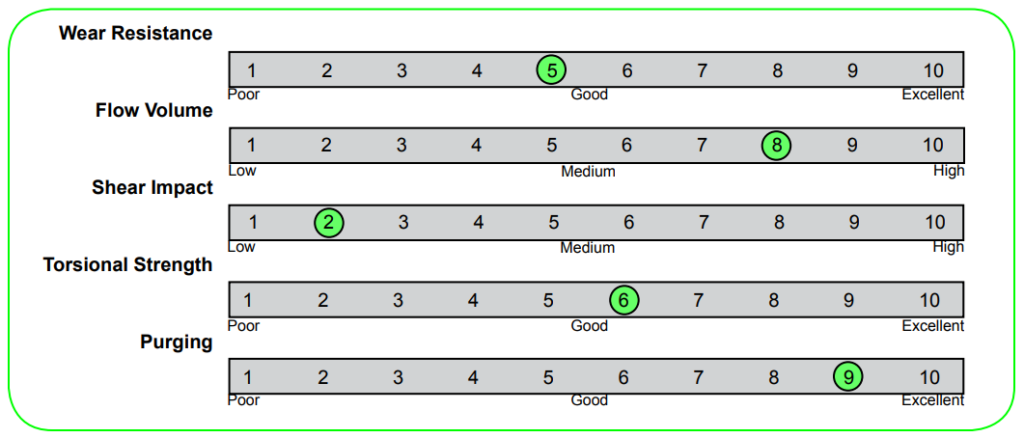

| Recommended Applications: | Recommended for use on shear or compression sensitive materials, general purpose materials and “limited runtime” filled materials. Use on highly fiber filled materials will maintain fiber integrity and result in higher tensile strengths in the molded part; however, faster wear of the valve maybe experienced. | |

| Limitations: | The P-700 design may not perform well on applications requiring high or moderate screw speeds or that utilize greater than 75% of the injection capacity. The abrasive action of the ring-to-stud contact at fast or prolonged use will generate heat that may anneal the hardness of the tool steel. Applications using moderate to low viscosity polymer may experience shot control (cushion) problems. The higher flow volumes of this design may allow these polymers to escape before a solid seal is created and cause an imbalance of pressures. |

|