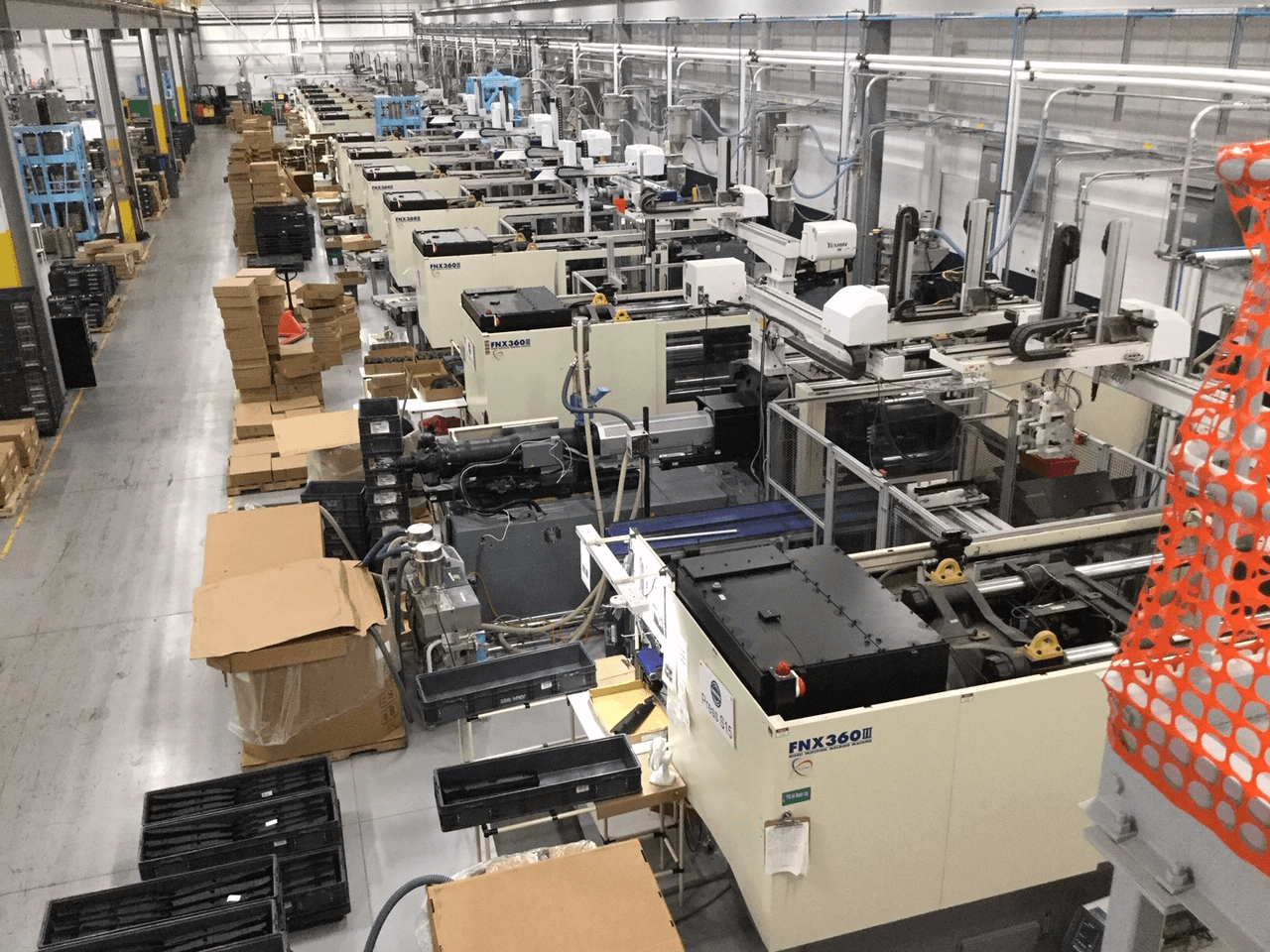

As a Nissei representative in Michigan, we have a vast knowledge of Nissei machines. With over 70 years of specializing in injection molding and innovation, Nissei provides a range of products to fit any job.

History of Nissei

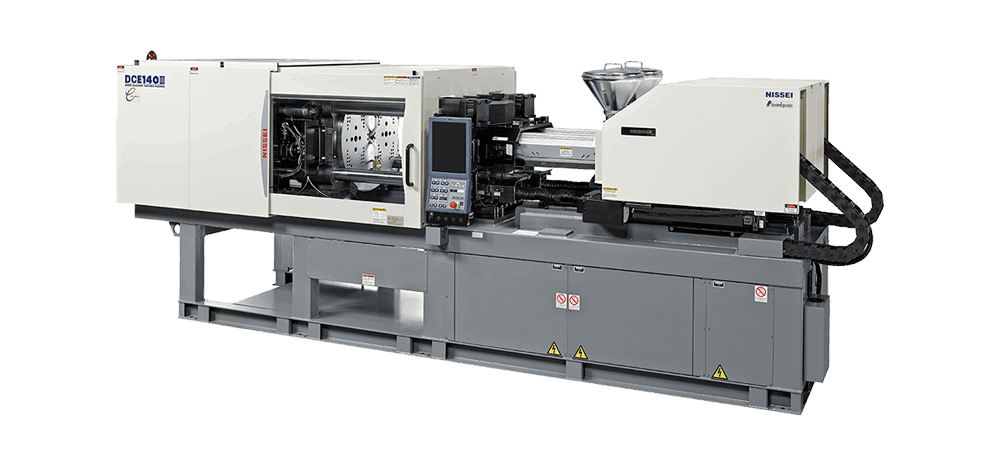

Founded in 1947, Nissei has created innovative machines for various industries. Soon after their inception, they began perfecting their molding machines, with the DC Series injection molding machines designed for two-color products.

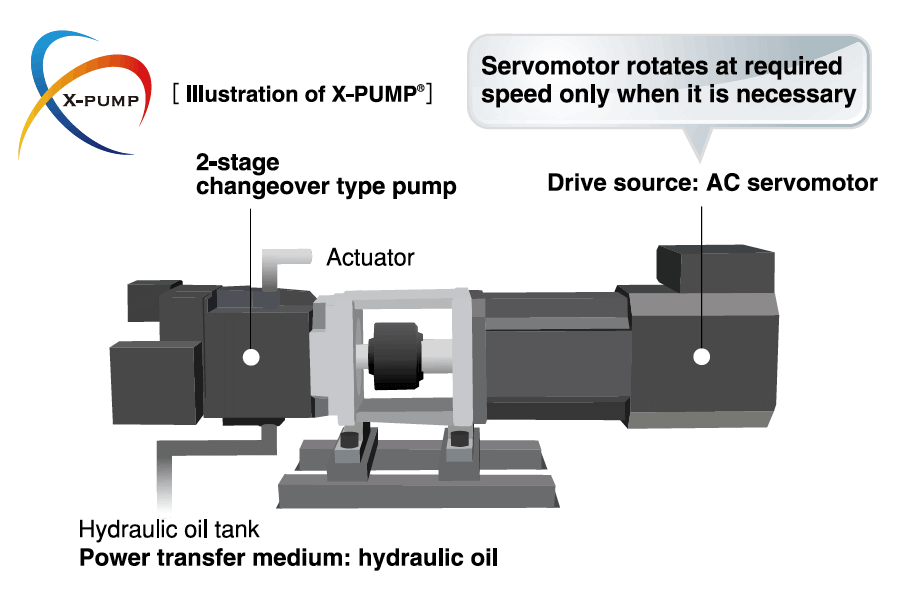

Nissei also revolutionized the hydraulic machine market with their exclusive X-Pump Technology, which culminated in hydraulic expertise and servomotor drive technologies. Nissei has continued to improve these products to create even more state-of-the-art machines, bringing the company to its current offerings.

Types of Nissei Molding Machines

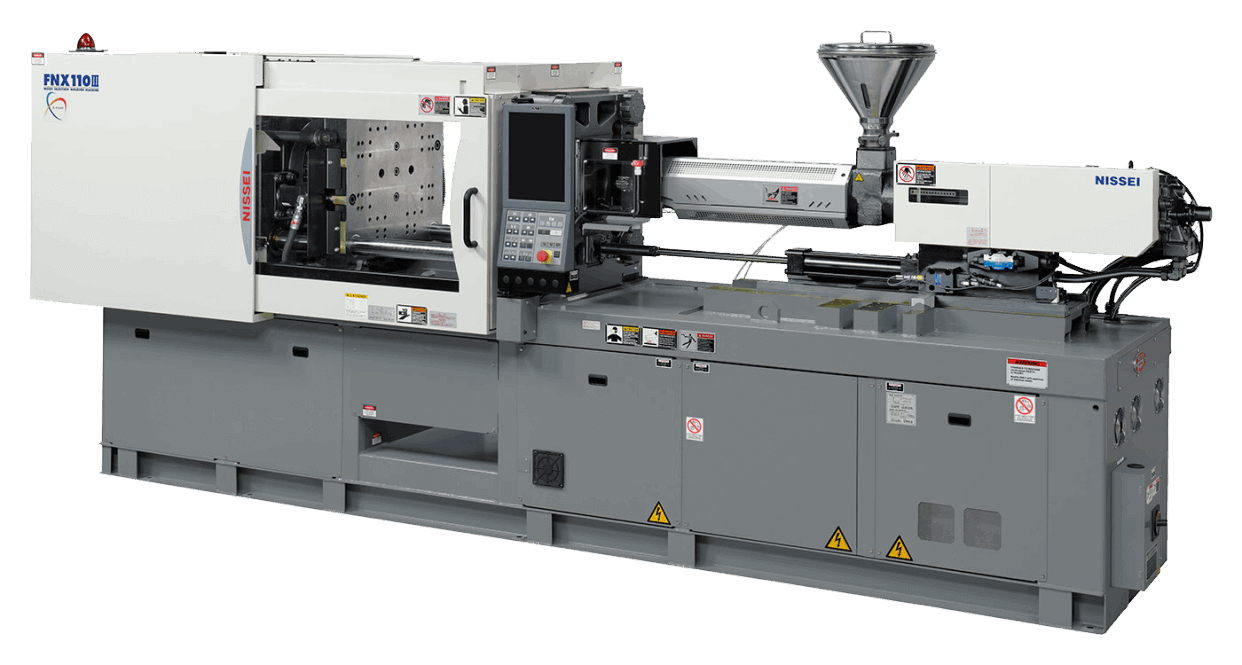

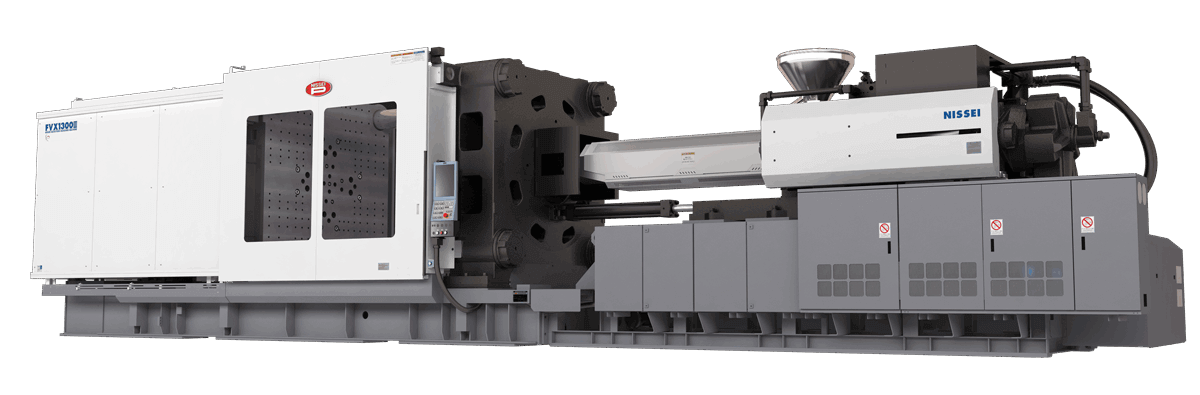

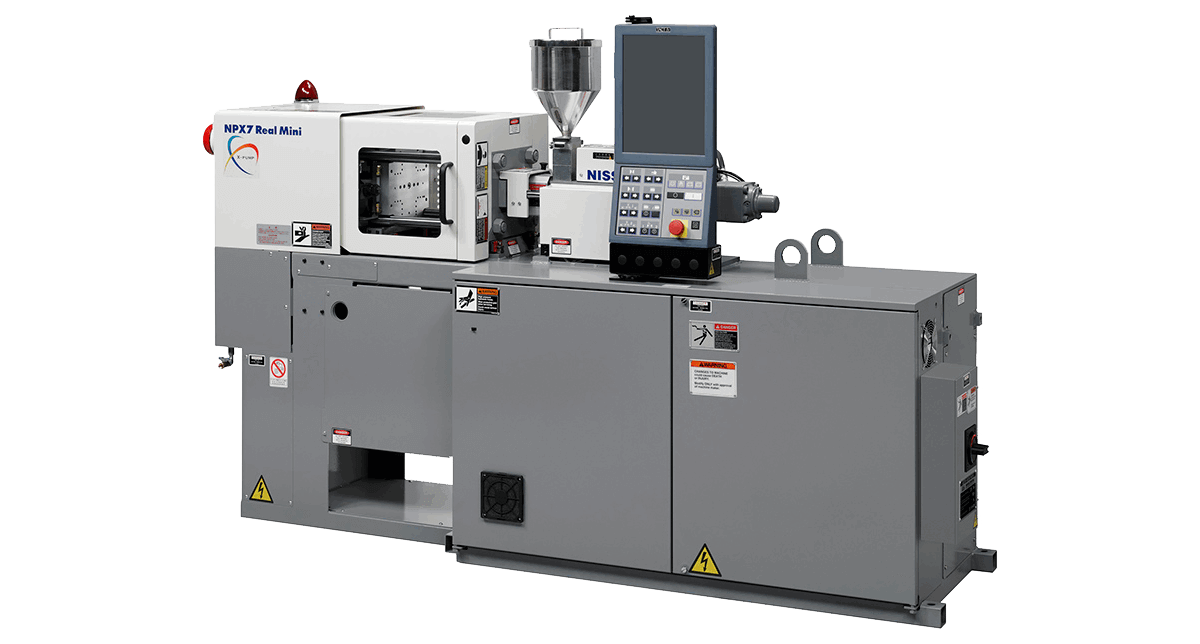

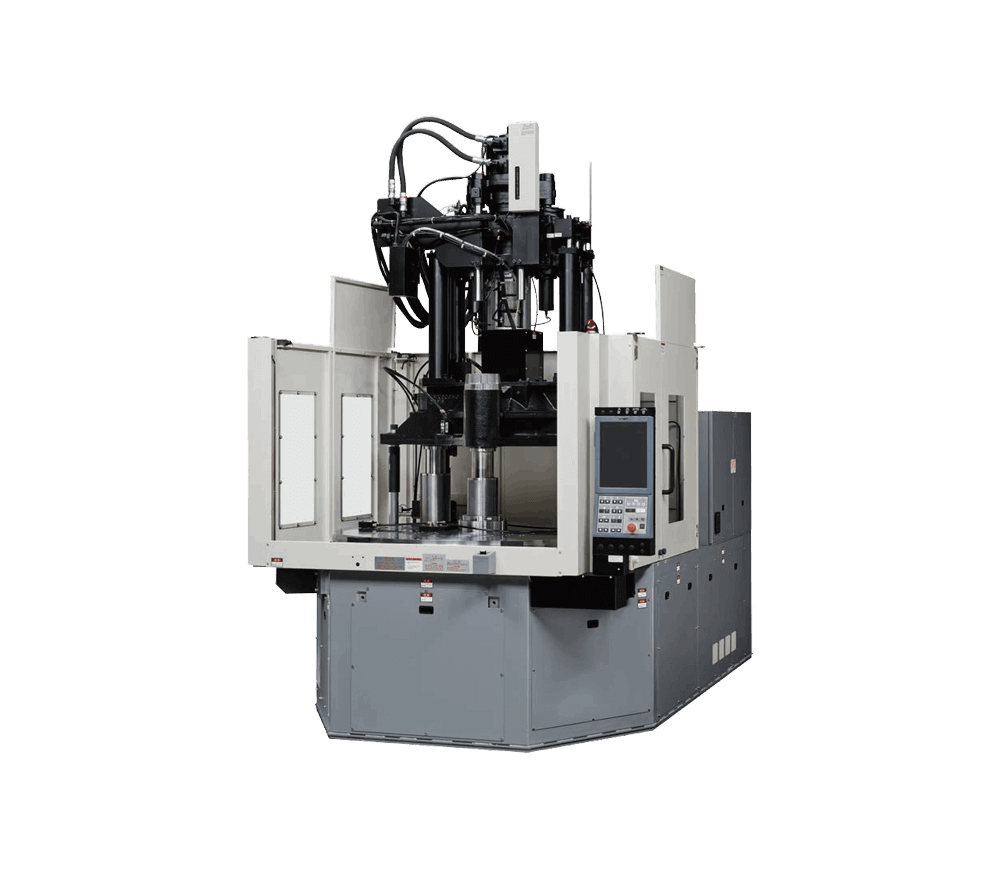

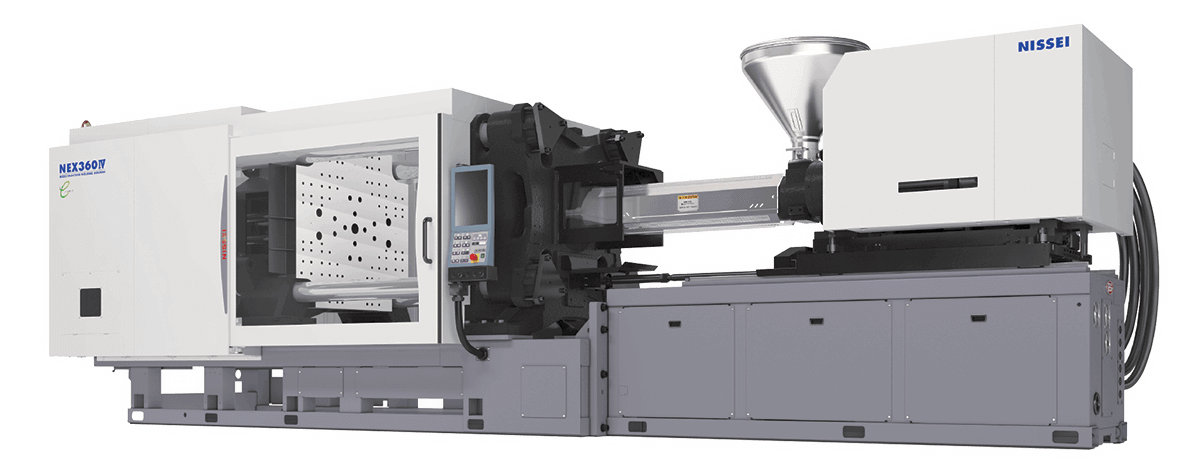

Nissei carries various high-quality molding machines to meet their consumers’ needs, including the Nissei blow molding and plastics machines. The wide selection of their molding series equipment ensures Nissei plastics machines can handle any job.