Photos

SURE-SHOT

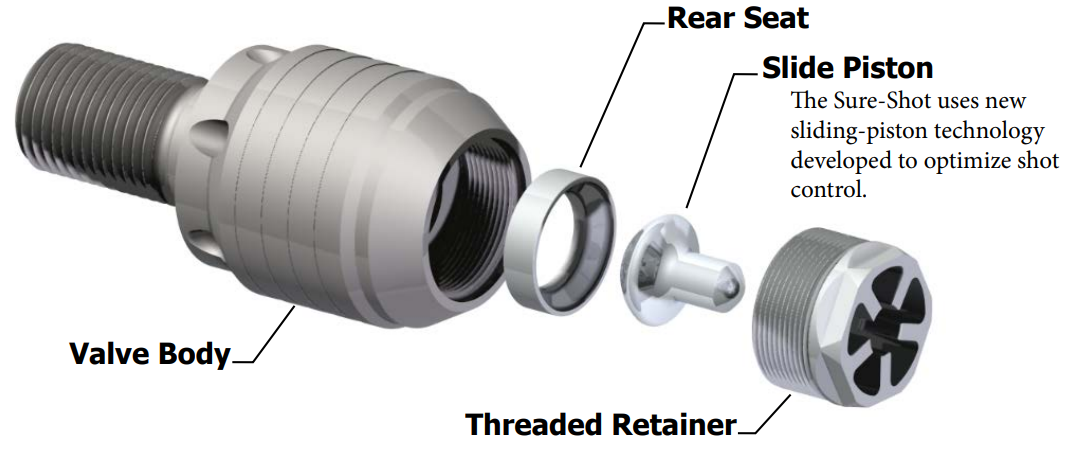

“SURE-SHOT” General-Purpose / Fixed-Rotation / Slide Piston Shut-off

The Sure-Shot screw tip offers the best in class performance to meet the needs of today’s most challenging molding applications. Offering quick, precise and consistent shot control. Sure-Shot makes it very easy to process any polymer regardless of it’s viscosity. Sure Shot valves are offered in sizes from 50mm up to 260mm. Unlike many suppliers, the Sure Shot has 8 different sliding-piston sizes to maintain high flow volumes across the entire product size range.

Specifications

“SURE-SHOT” General-Purpose / Fixed-Rotation / Slide Piston Shut-off

| The Sure Shot non-return valve is the first of its kind developed with flow dynamics that provide little or no pressure drop thru the valve greatly reducing shear in the polymer. This also allows for faster recovery times. | ||

|---|---|---|

| Materials: | Designed with removable wear components and manufactured from high quality tool steels the Sure Shot offers both the necessary strength and durability for long term operation. The main body can also be supplied with a Tungsten Carbide coating on the outside diameter. | |

| Benefits: | Unlike floating ring valves the Sure Shot is suitable for high screw speed applications. The valve body has been designed to minimize surface contact area with the barrel to reduce heat build-up and galling. | |

| The Sure Shot reduces or eliminates the need for screw decompression sometimes referred to as suck-back. | ||

| Limitations: | Purging and Color Change - Our flow path design with very steep internal flow angles optimizes direct flow and self-cleaning. Sure Shot features the most flow channels in the industry. This eliminates dead flow zones between the valve and the feed screw. Every Sure Shot is designed with six flow channels allowing the polymer to evenly flow from the feed screw. |

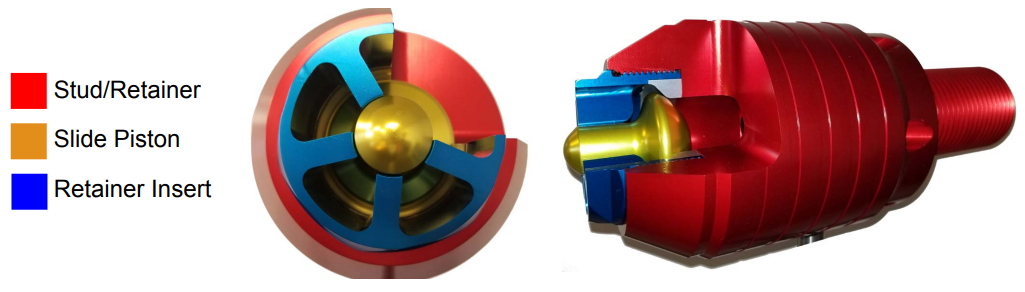

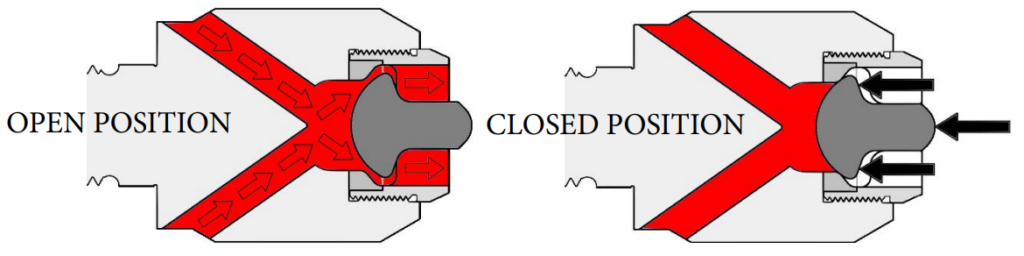

Shut-off is controlled by a sliding-piston which is designed to react instantly as the screw moves forward sealing back-flow. The design causes the pressure behind the piston to decrease and the pressure in front of it to increase as the screw begins to move forward creating a fast acting and positive shutoff.

|